Building on the results of the sprint Smart Digital Twin, the automated warehouse system was retrofitted with new sensors.

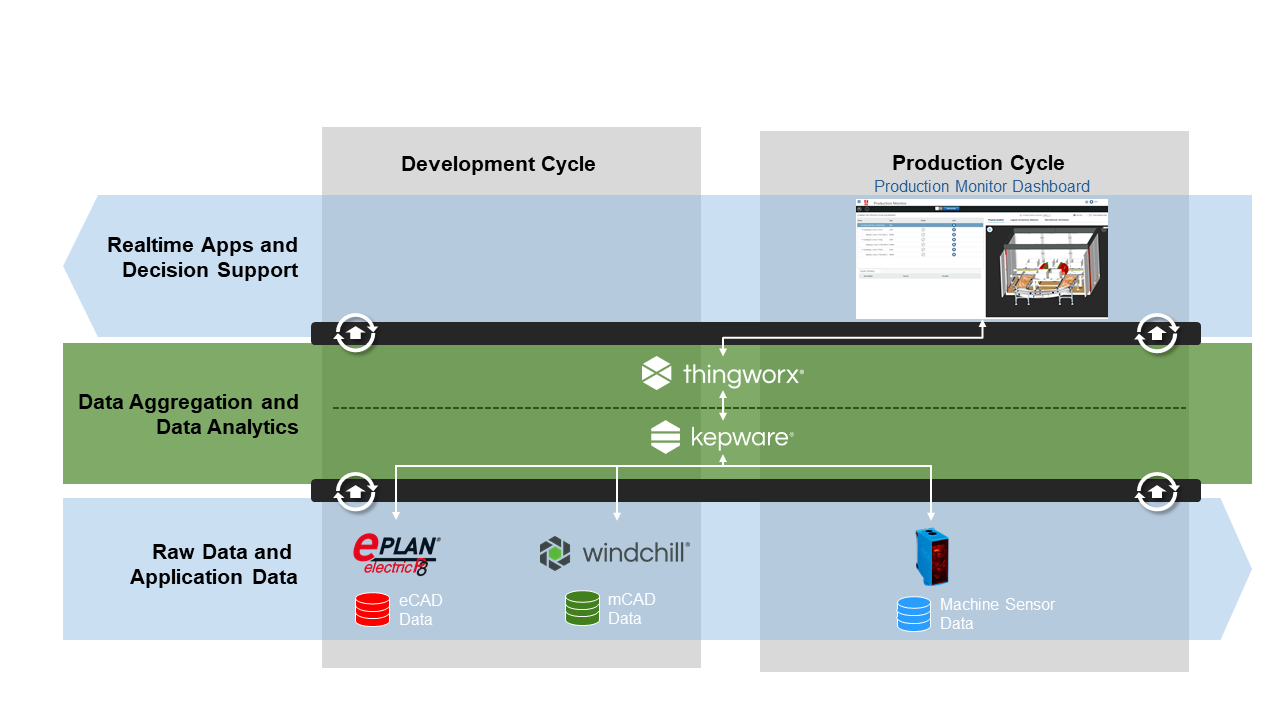

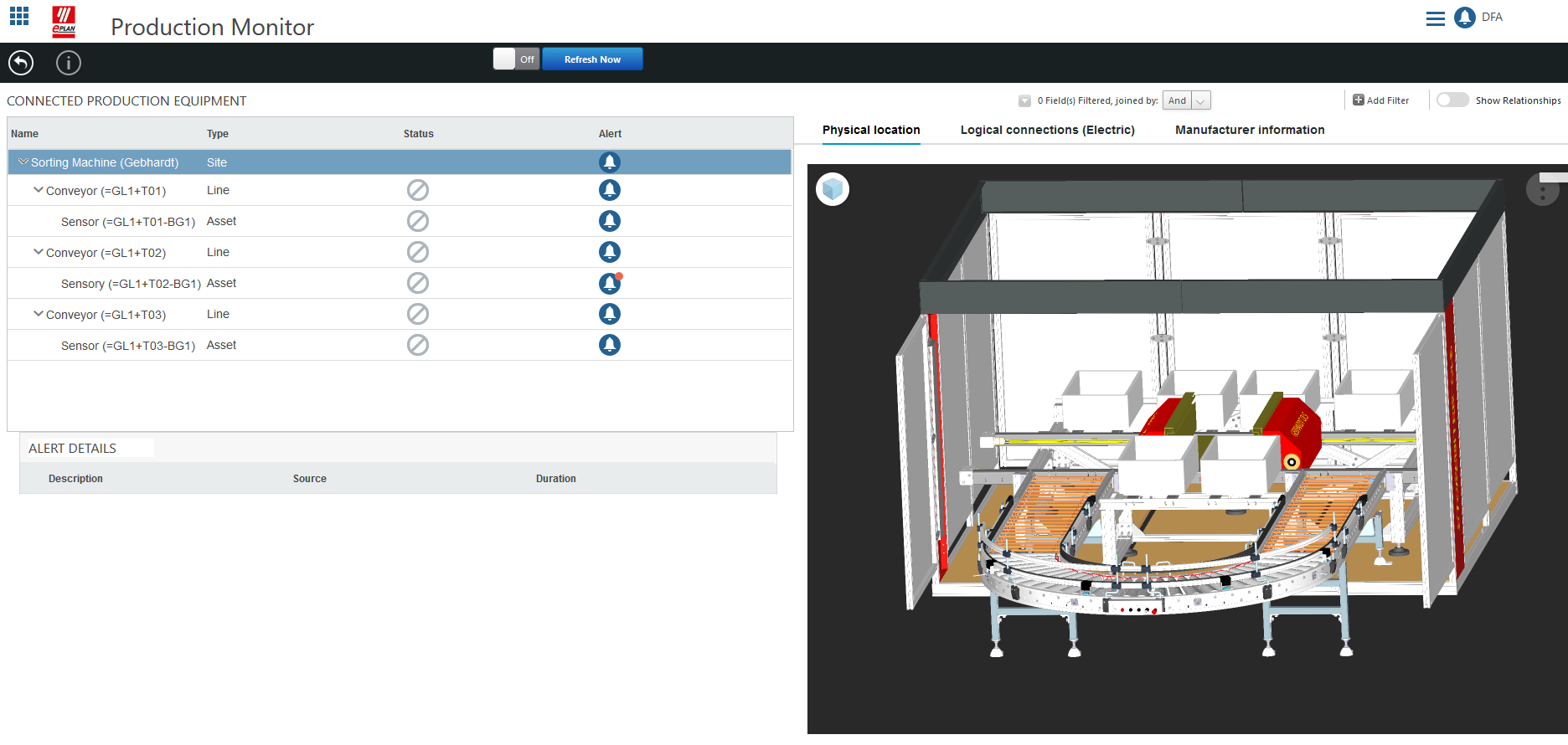

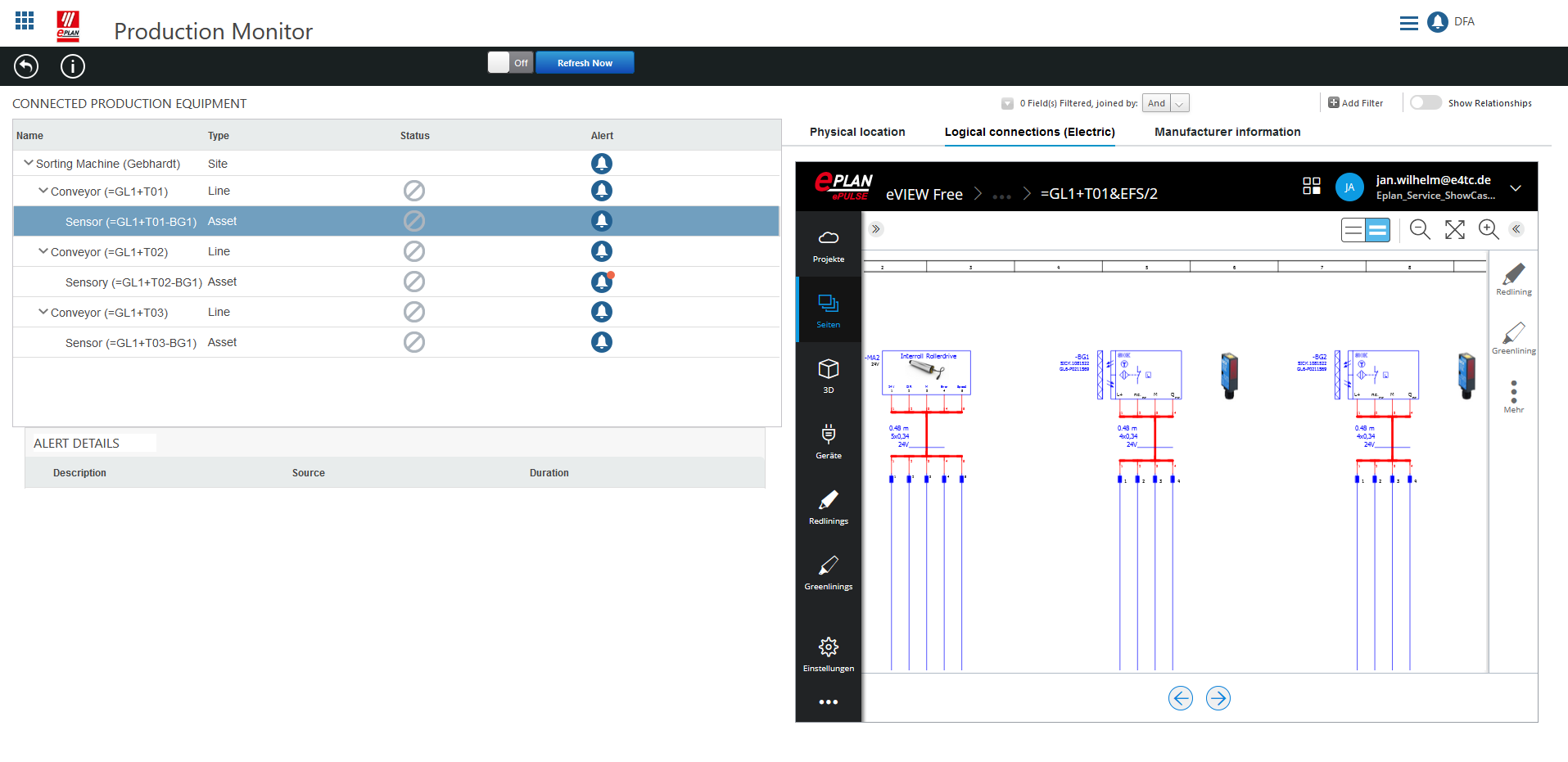

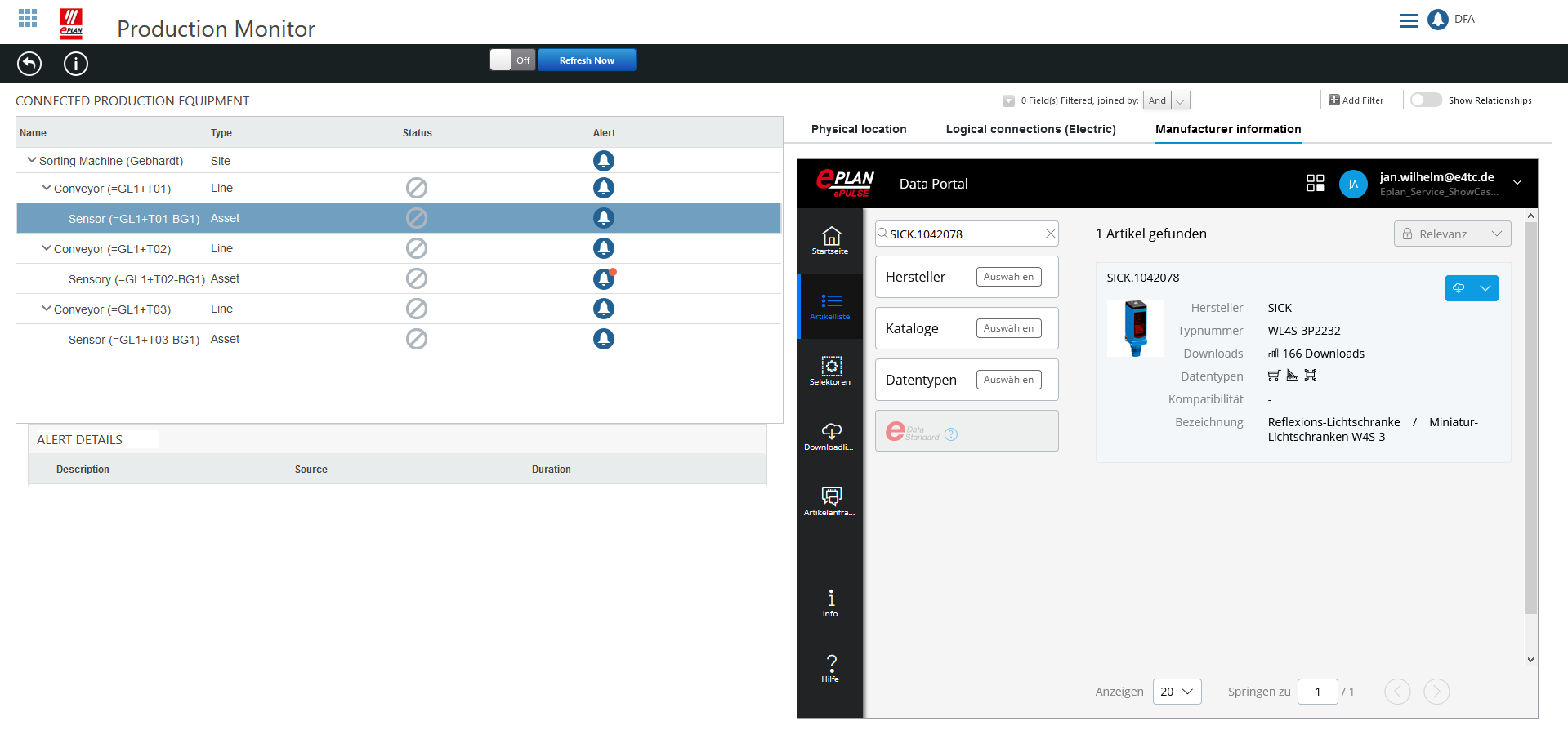

The sensors send information on the current machine status to an IoT gateway in real-time. As soon as there is an error, the affected component is visible to the machine operator at the web front-end. By combining MCAD and ECAD data into a single application, maintenance has all information from a single source. Via the IoT-platform, the component to be fixed is linked to mechanical 3D construction data, circuit diagrams, and manufacturer information. Maintenance staff can thus access all relevant information in an intuitive decentralized web front end, e.g. about damaged components that need to be replaced. The application not only helps to monitor asset condition in real-time, but provides asset information across development disciplines at the click of a button. This way, the Smart Digital Twin Maintenance reduces maintenance time while at the same time increasing machine availability.