Having the right material at the right place at a specific time is the core task of intralogistics. Optimized route guidance plays a crucial role to efficiently connect warehouse and place of consumption in order to minimize waste. While experienced employees are rather proficient at finding the shortest route, new employees need more time to find the exact destination of their next delivery, resulting on more frequent misdeliveries. Especially for companies with a high process- and product variance, this poses severe challenges for logistics personnel. A solution that is both intuitive to operate and understandable without language barriers was to be created. (learn more)

The case of an automated warehouse system highlights the potential of digitalized and connected operating resources for production and maintenance. ECAD data is joined with MCAD data and prepared for visualization through augmented reality. This opens the possibility to obtain information on the wiring diagram as well as the construction plan in one single app. For maintenance, this leads to an enormous time advantage when identifying and replacing defect mechatronic components. Augmented reality supports maintenance staff with respect to both the identification of the defect component as well as the layout of the switch cabinet.

In general, manual assembly processes start with the identification of the screw case at the assembly piece. Based on the recognition, the correct process parameters have to be selected to ensure a safe and high-quality screwing. The data, e.g. in form of screw curves has to be documented and saved in a quality management system. The results of the project “Smart Assembly Quality Control” support the worker in all the steps of the process. (learn more)

To realize a digitally connected factory in the spirit of industry 4.0, a bi-directional, real-time, and web-based communication with machines and production assets is a basic building block. Especially brownfield production environments are a great challenge for creating a sound basis for data and communication: At machine level, data comes from different sources in various formats, often a wide variety of interfaces must be taken into account. These challenges are addressed by the IIot connector box, where all existing machine data as well as retrofitted sensor equipment are brought together in a standardized solution. (learn more)

One problem of unplanned downtime in practice is that machine information typically is not bundled in one place. Mechanical and electric information as well as manufacturer information are sometimes not digitally available or scattered over several databases. The resulting search effort costs negatively affect a timely fixing of the problem. The Smart Digital Twin Maintenance merges all relevant machine information across disciplines in a browser interface. This way, maintenance is able to detect and fix errors significantly faster. (learn more)

Even though the wiring connections of cable cabinets are nowadays mostly stored digitally, a media break occurs at the assembly stage Typically the technician responsible for wiring of the individual components in the switch cabinet, prints out the instructions. This circumstance causes time-consuming and complicated searches for the right connections and is a time-consuming/non-value-adding method of working. In addition, errors become more likely.

In the project SmartWirAR, an augmented reality based system was developed overlays the physical workplace with the digital plans. Connected tools lead through the wiring process. (learn more)

In cooperation with the member companies Miele, PTC, Bossard, Elisa, and Atlas Copco, the E4TC developed an One-Piece-Flow 4.0 for assembly. The project is realized at the demonstration factory at the RWTH Aachen Campus.

Equipped with location sensors, a digitally connected assembly tool can be used at each assembly station. Product, tool, sensor data, bill of material and process plans are integrated through an IoT platform. The smart tool retrieves the correct parameters at each assembly station automatically. All assembly steps are reported and documented without the need for manual intervention. The location tracking ensures that the assembly tool can only be used at the designated assembly stations. The smart assembly station minimizes waste and increases both flexibility and quality of the assembly process.

Laser cutters used in industry cut up to 300 parts into a single large sheet metal. To ensure sustainability the amount of waste should always be kept at a minimum In order to do so, parts usually are spread randomly all over the sheet metal rather than sorted. While this optimizes the amount of waste, it makes it more difficult and time-consuming for a worker to identify all the parts and sort them accordingly. The parts on the sheet might differ from one to another and can even belong to different orders or customers.

Together with PTC and Trumpf, we developed an Augmented Reality-based (AR) app for operators to distinguish the parts and thereby speeding up the sorting process. (learn more)

At the e.GO series factory in Aachen, the end of line quality inspection is supposed to follow the assembly cycle time of 10 minutes per station. At the same time, information from the quality check and inspection results have to be documented and stored digitally. With around 400 relevant quality aspects being tested, an efficient process is only possible with the help of a digital tool. (learn more)

A high degree of transparency is needed in modern manufacturing sites. In execution planning, for example, all individual production steps need to be planned down to the finest detail. This requires constant knowledge of the location of equipment, tools and materials. The combination of an asset tracking solution that is standardized and hardware independent, with the opportunities of data analytics offers not only real-time insights into order flows but even make it possible to predict situations on shop floor. This optimizes the entire order flow and value chain within a production site. (learn more)

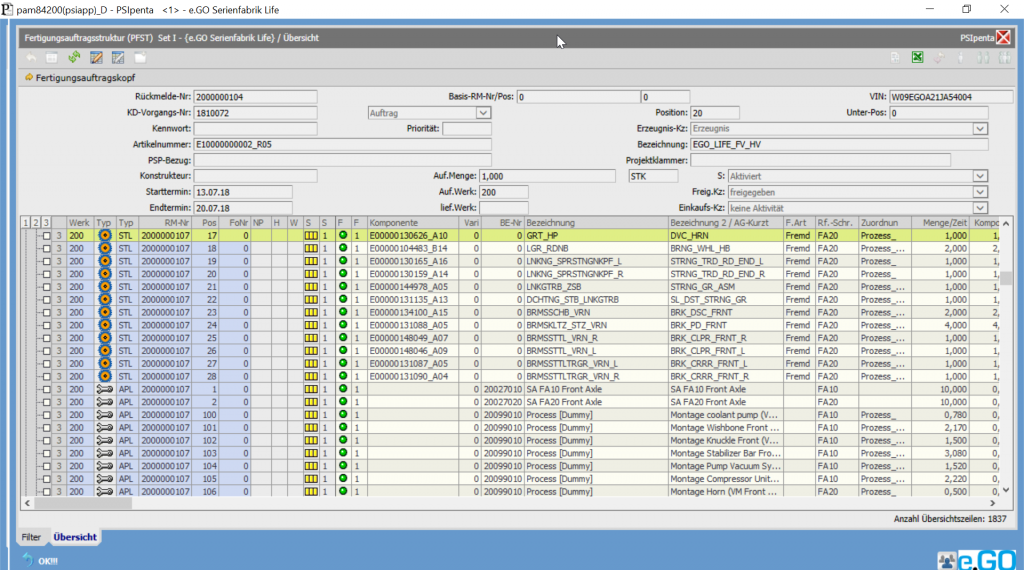

e.GO Mobile AG uses PSIpenta as their ERP system. Through an interface, the manufacturing bill of material (mBOM) and the bill of process (BOP) are automatically transferred from the PLM system to feed the ERP master data which are enriched with additional information. Customer orders are sent to PSIpenta from a webshop that is linked to a sales product configurator. The ERP System that schedules the customer orders based on resource availability. All material necessary for production is calculated, ordered and managed in the system.

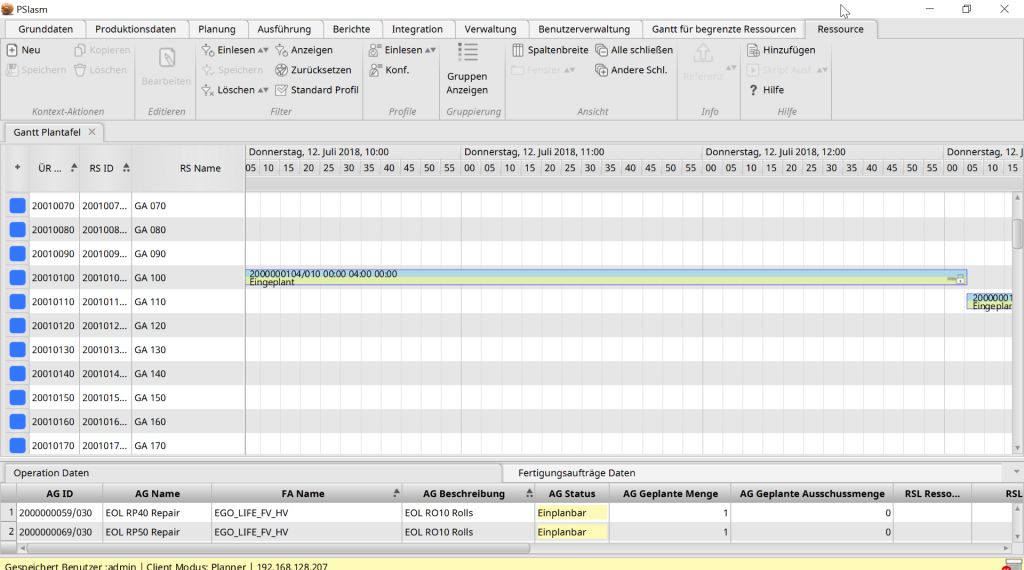

Based on the production orders from the ERP, the production management tool ASM allows for manually sequencing the production orders within a shift or a day. The execution of this defined sequence is supported by the MES system for work instructions and recording feedback.

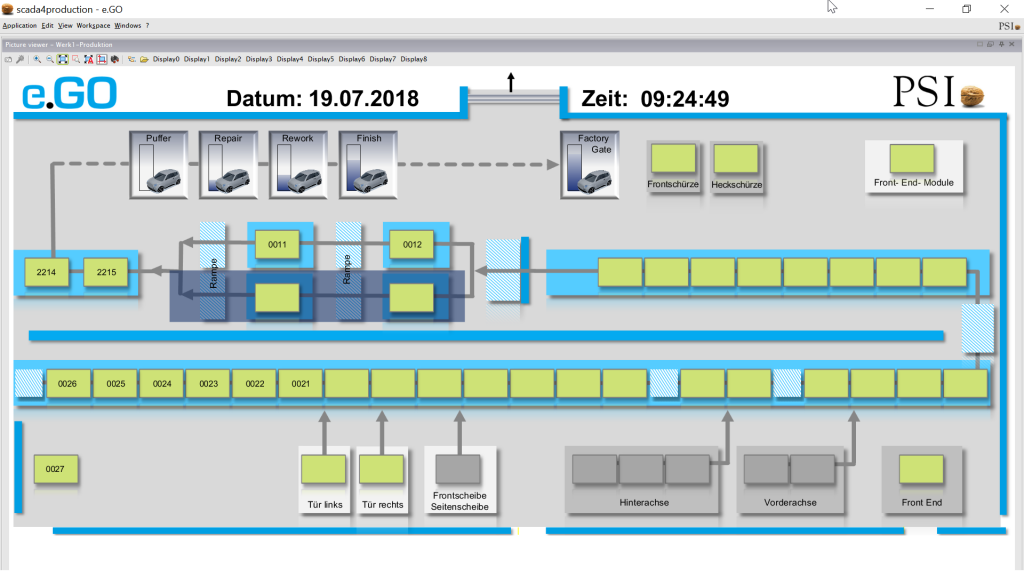

The sequenced and running production orders for pre-assembly and final assembly stations are visible in a bird‘s eye perspective on the SCADA screen. Based on real-time data from the manufacturing execution system (PSI MES), the SCADA screen offers an overview of current assignment as well as status of all assembly stations. The order numbers show which order is currently at which station. An intuitive colour coding signals whether interventions are necessary.

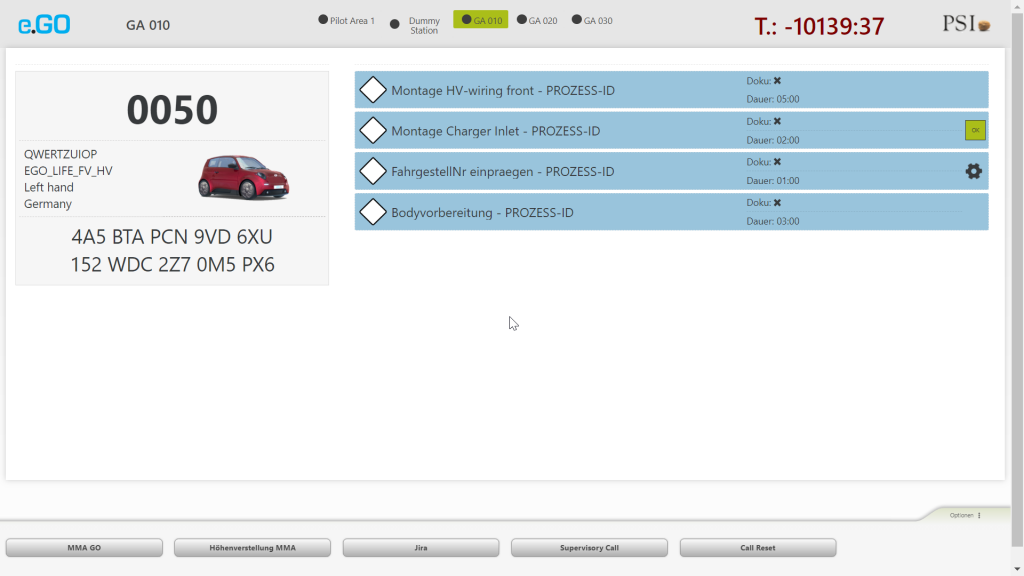

e.GO’s pre-assembly and final assembly workers have monitors in their stations to receive their task list for each production order. The MES displays the tasks resulting from the bill of process (BOP) per production order and the planned order sequence. This covers all production steps and their cycle times. On the touch screens, workers can sign off on every step. Together with additional automated feedbacks from connected equipment, the seamless documentation of the whole production process, meeting regulatory requirements, is ensured.

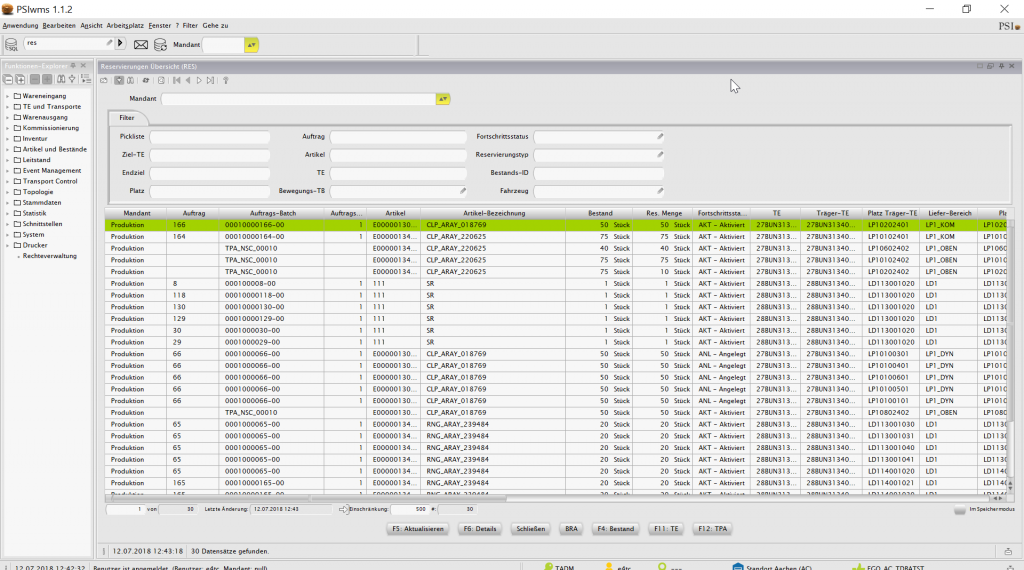

PSI WMS controls all flows of materials within the e.GO series production plant. This includes material in stock, consumption on the shopfloor, commissioning as well as re-stocking of material along planned routes. Through small android-based scanning and display devices (MDT), logistics workers are guided step-by-step, while the system automatically priorizes the orders in the background. Workers use MDT to enter completion notes and feedback back to the system.

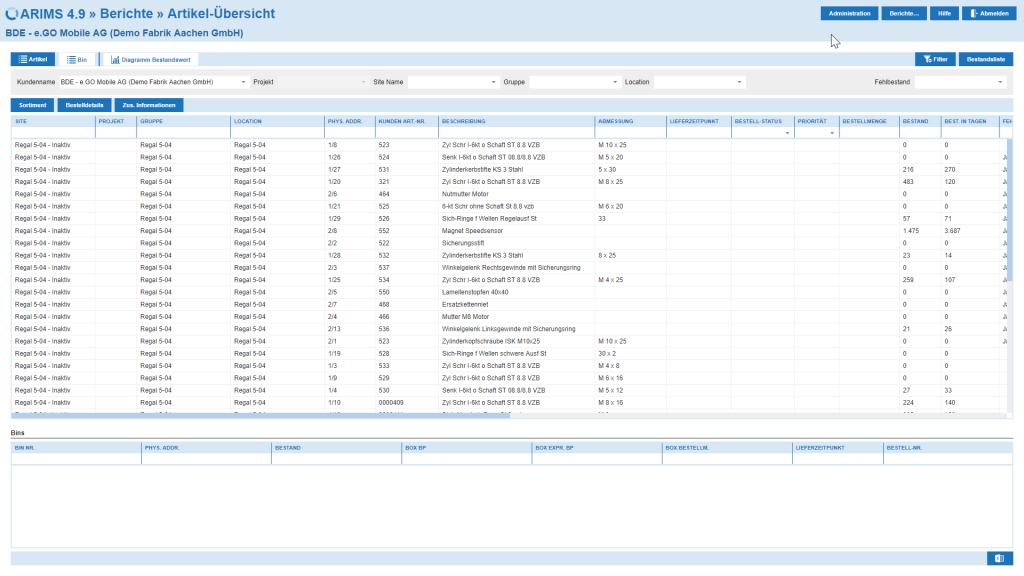

Bossard does not only offer fastening solutions, but also automated replenishment services based on the „availability-to-line“ business model, i.e., outsourcing the C-parts-management from the manufacturer. Bossard‘s software ARIMS is the backbone of this digital business model. The system is driven by smart bins that constantly monitor stock with the help of integrated weight sensors and trigger replenishment automatically.

The Demonstration Factory Aachen applies a multitude of sensors, IT systems and connected machinery. The digital shadow creates a digital representation of all connected processes. Smart Factory, the cloud-based internet-of-things-platform by Elisa visualizes monitoring and system data in a three-dimensional mirror image of the site allowing for drill-down into process and equipment details. This enables real-time monitoring of any factory or production line through intuitive apps based on 3D visualization.

The Aachen eLAB owns a battery cell production line that is equipped with sensors and cameras. Minimizing scrap is very important, as defect battery cells can only be discovered post maturation, some weeks after the start of the production process. Optical monitoring with a high performance camera, and the real-time analysis of relevant process parameters such as temperature or coating density allow to understand this context and enable targeted process improvements. This E4TC project combines Elisa, HPE and PTC solution elements.

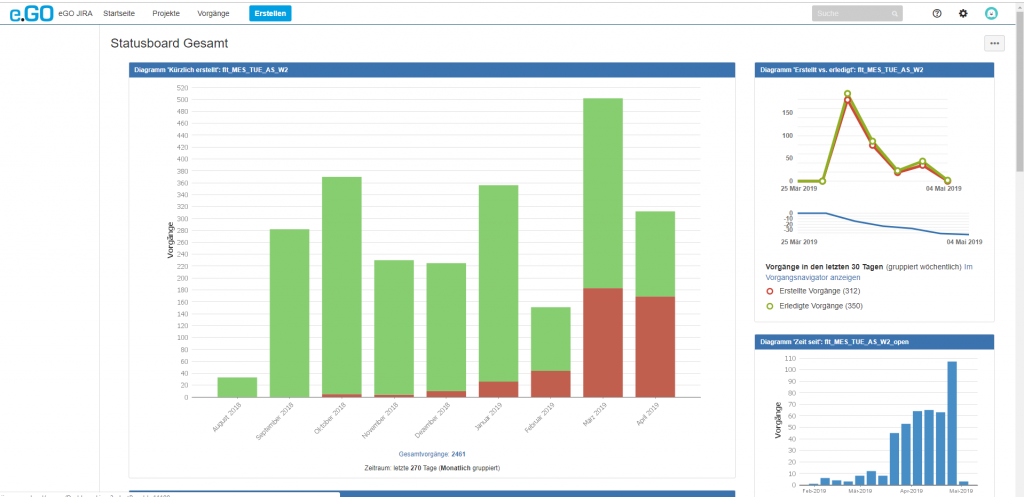

For the production ramp-up of the e.GO Life, it is crucial to identify and document all emerging problems and challenges on one dedicated platform that communicates with all relevant stakeholders. Problems and their respective solutions can be traced one-by-one. This provides online status and content for improvement execution and regular status meetings.