Sprint description

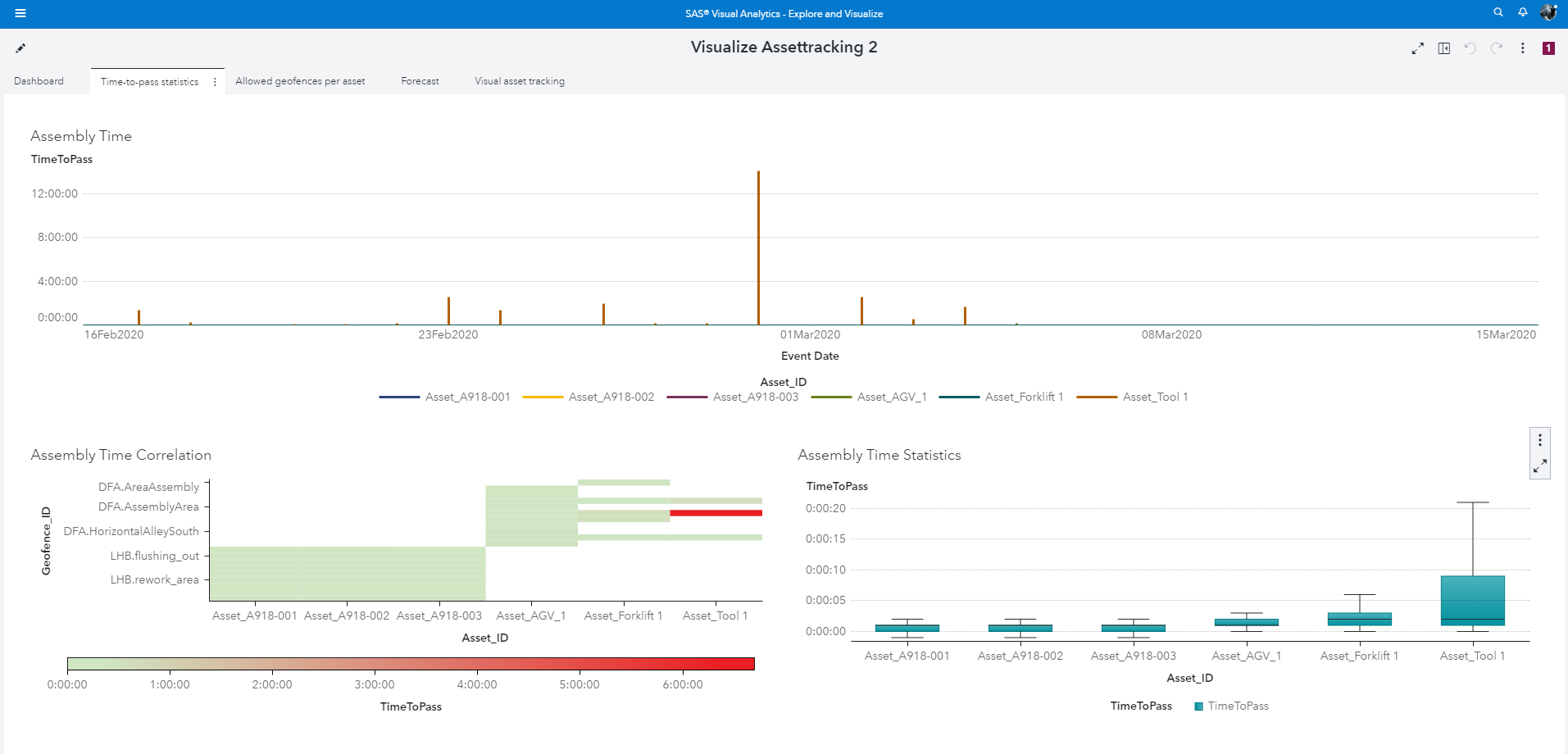

At the Demonstration Factory of RWTH Aachen Campus, the project was realized taking into account the Internet of Production architecture, as silo applications are proprietary and not flexible enough. Visualisation of the planning data and a graphic representation of the position of individual components are required. Depending on the localization technology, the real-time position reports were recorded and converted into global coordinates. Combined with the virtual representation of working areas the position data trigger events when passing through these areas. For easy and intuitive editing of virtual areas a 3D factory layout is used. The result is a calculation and prediction of throughput times, that are carried out simultaneously. The analytical results are provided in a web application and made available to external systems for further processing. This enables overall information regarding the current and predicted status of moving equipment, materials and orders.

The developed solution offers the following benefits:

- The recognition and optimisation of actual transport routes

- The acceleration of the assembly steps for individual production slots

- The reduction of setup times in the workspace

- And stocks at the assembly line are adapted to actual requirements