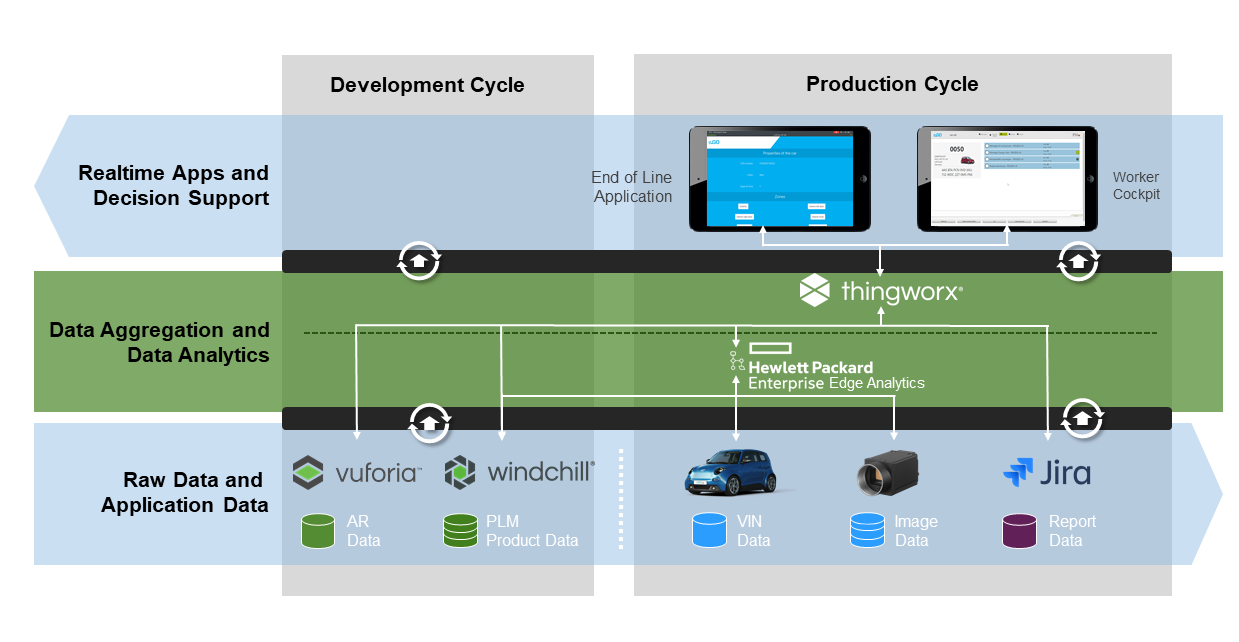

At the e.GO series factory in Aachen, the end of line quality inspection is supposed to follow the assembly cycle time of 10 minutes per station. At the same time, information from the quality check and inspection results have to be documented and stored digitally. With around 400 relevant quality aspects being tested, an efficient process is only possible with the help of a digital tool.

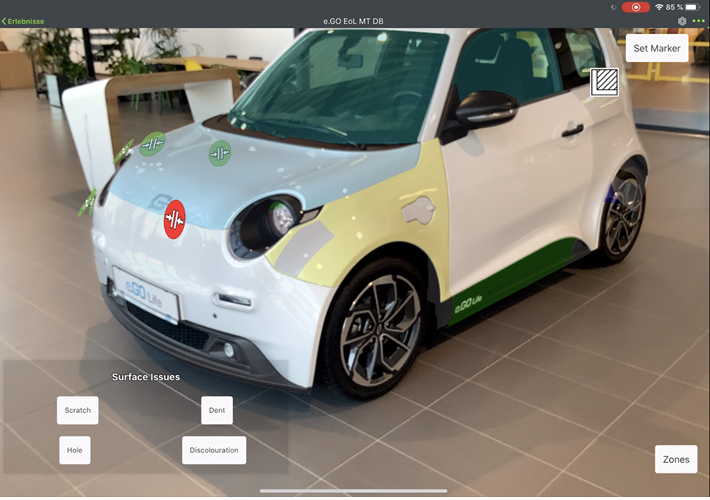

Objective of the E4TC project was the development of a solution that detects quality defects automatically through image recognition. The use of Augmented Reality allows an intuitive and fast execution of digital quality documentation processes.