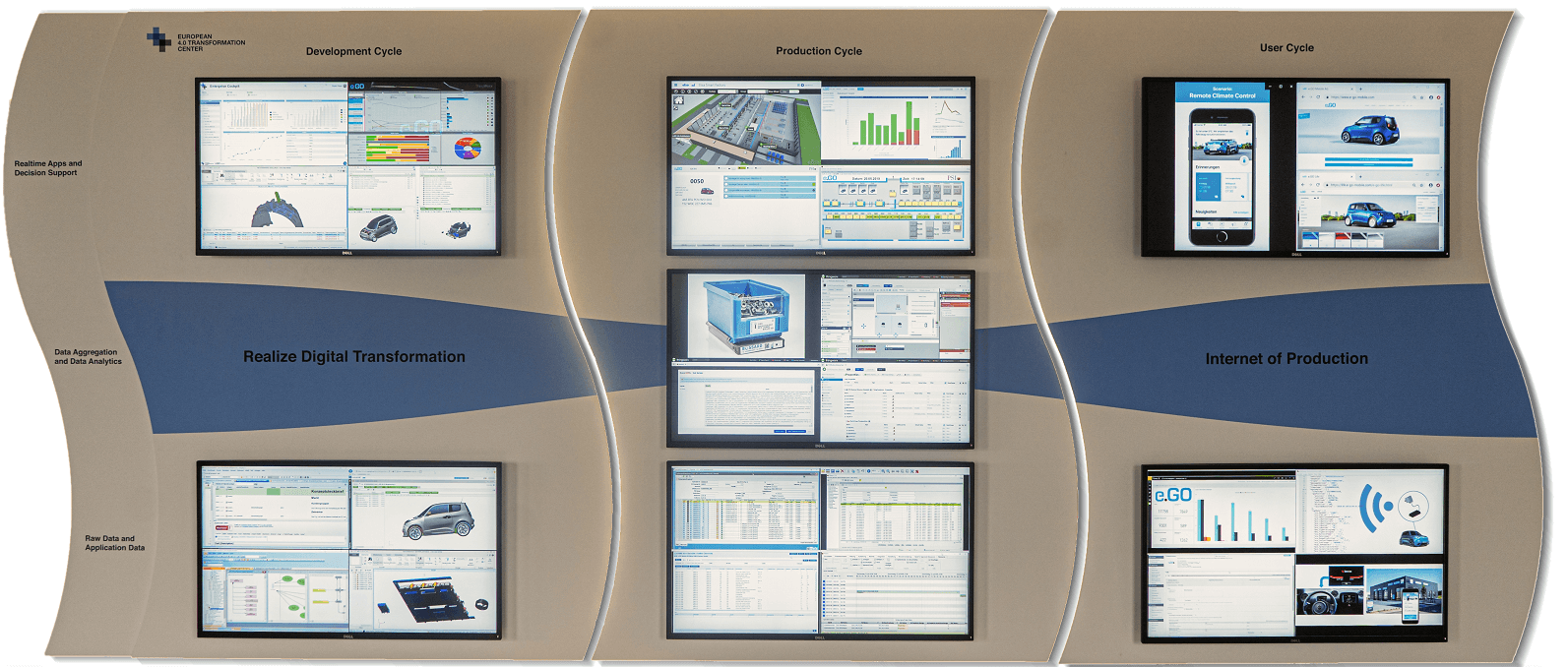

The Internet of Production approach ensures that data and use cases are available across departments, and can close loops traveling upstream with traceability, complementing traditionally sequential process and IT architectures.

As an electrical car start-up company, e.GO Mobile has been realizing the Internet of Production in an agile way and put it on display in e.GO’s Plant 1 series factory and in the Demonstration Factory (DFA) at RWTH Aachen Campus.

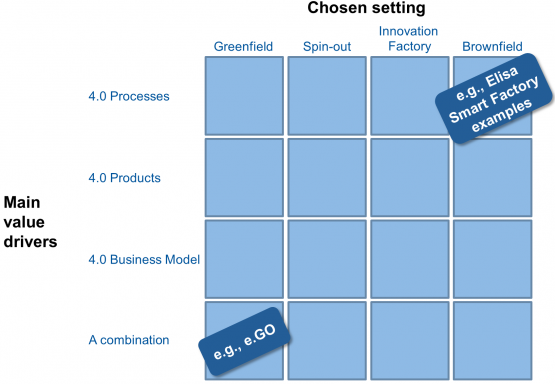

In order to chart a course for 4.0 Transformation that tackles these challenges and opens up to the available opportunities, we suggest to define a company-specific variation of the Realize Digital Transformation Roadmap.

Key benefits of such an approach include:

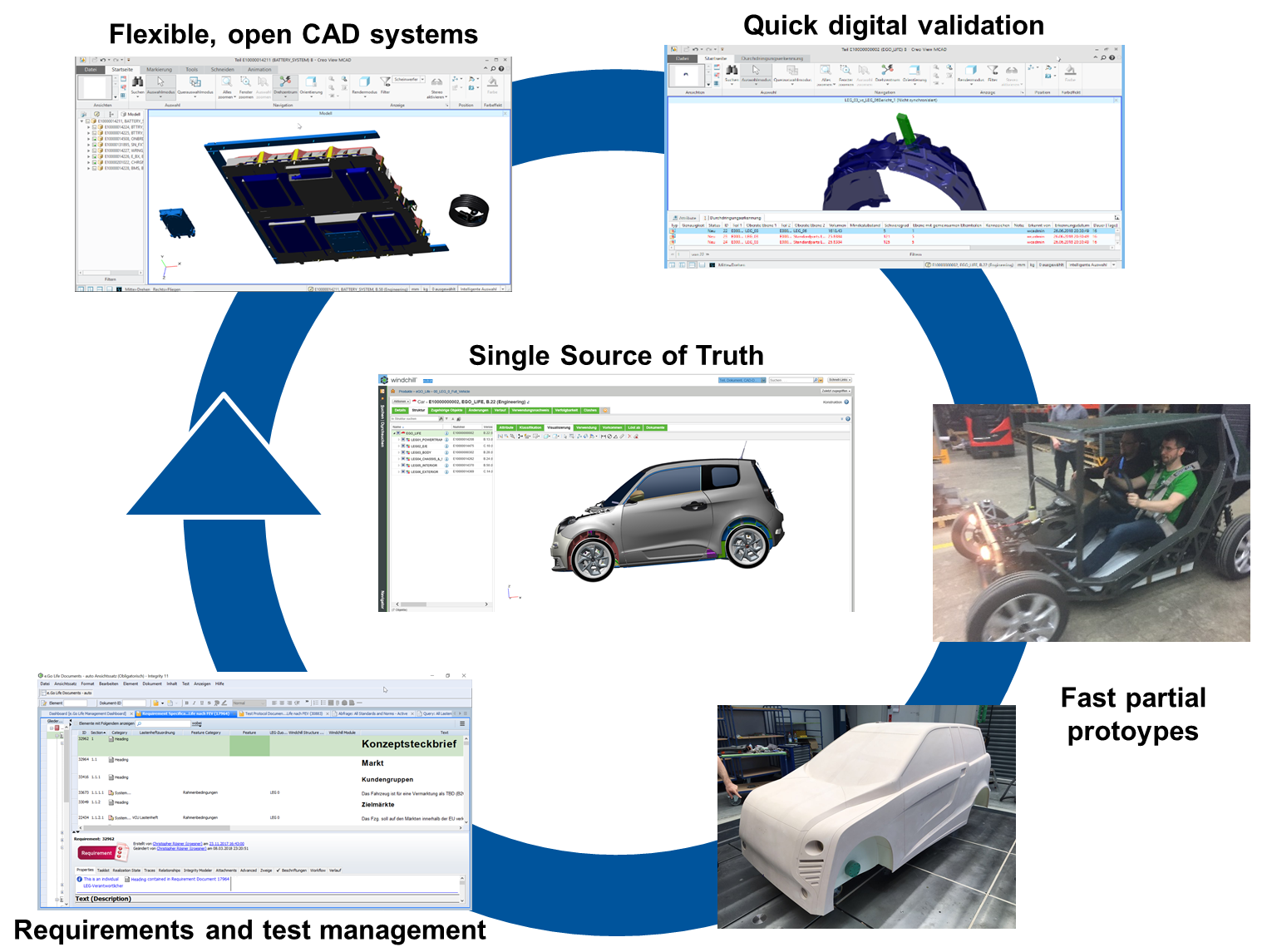

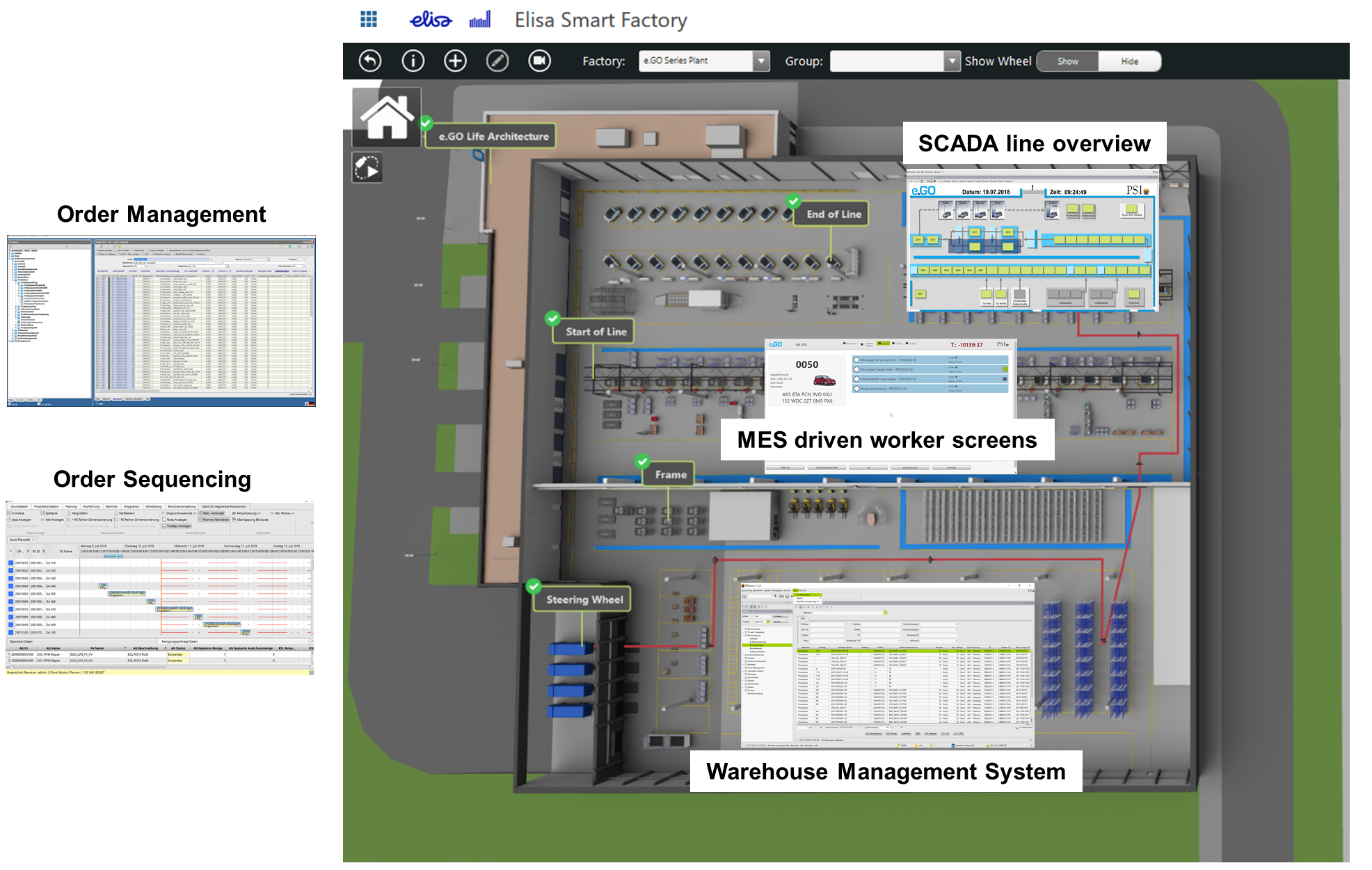

From an enterprise-wide perspective, given application landscapes are often the product of departmental history, with gaps relative to current requirements and inconsistencies between domains. Therefore, a tangible indication of the current state is the use of file-based information, like spreadsheets. Depending on industry and business type, potential target scenarios for seamlessness do vary. At e.GO, the three main areas are:

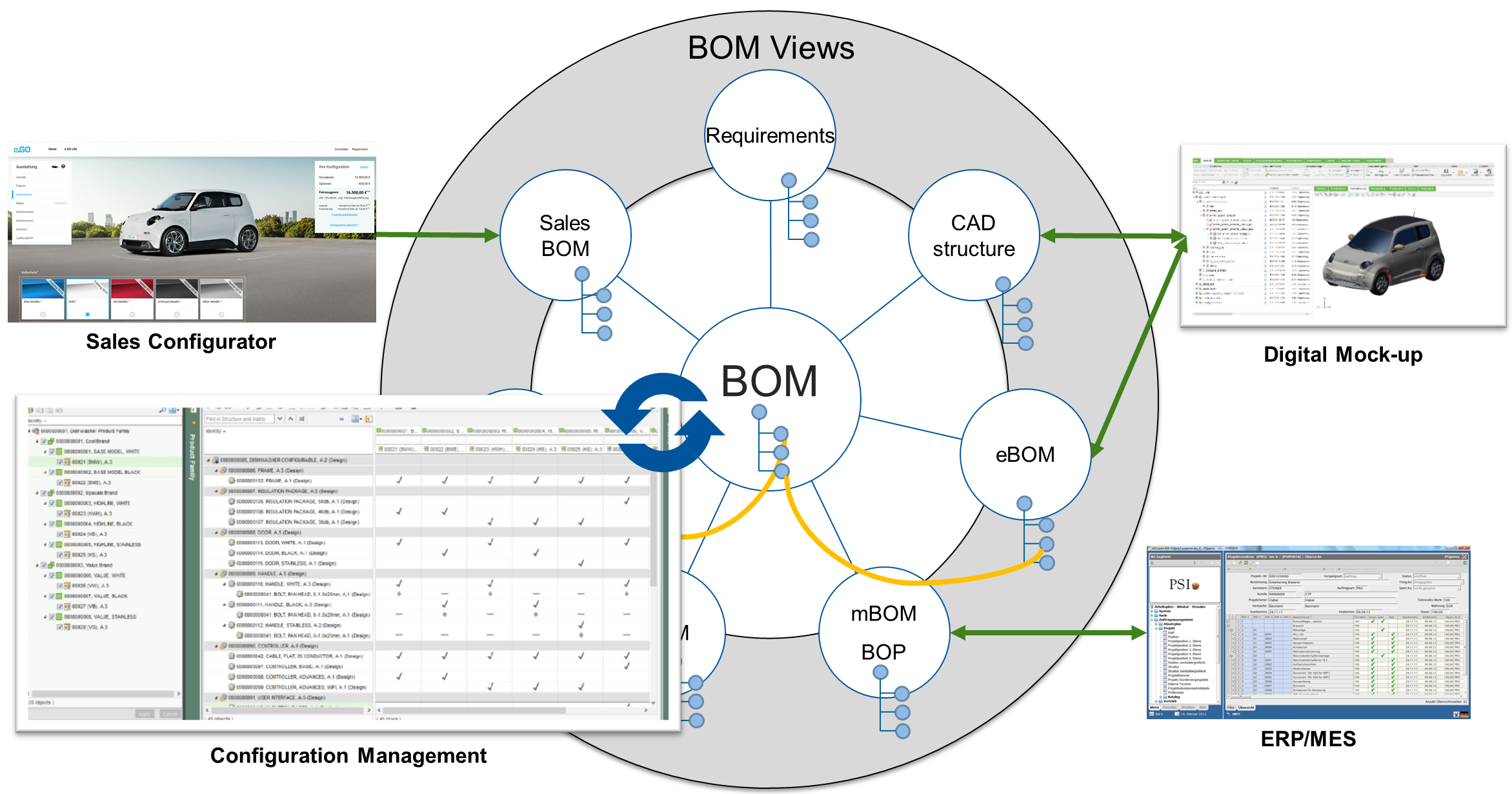

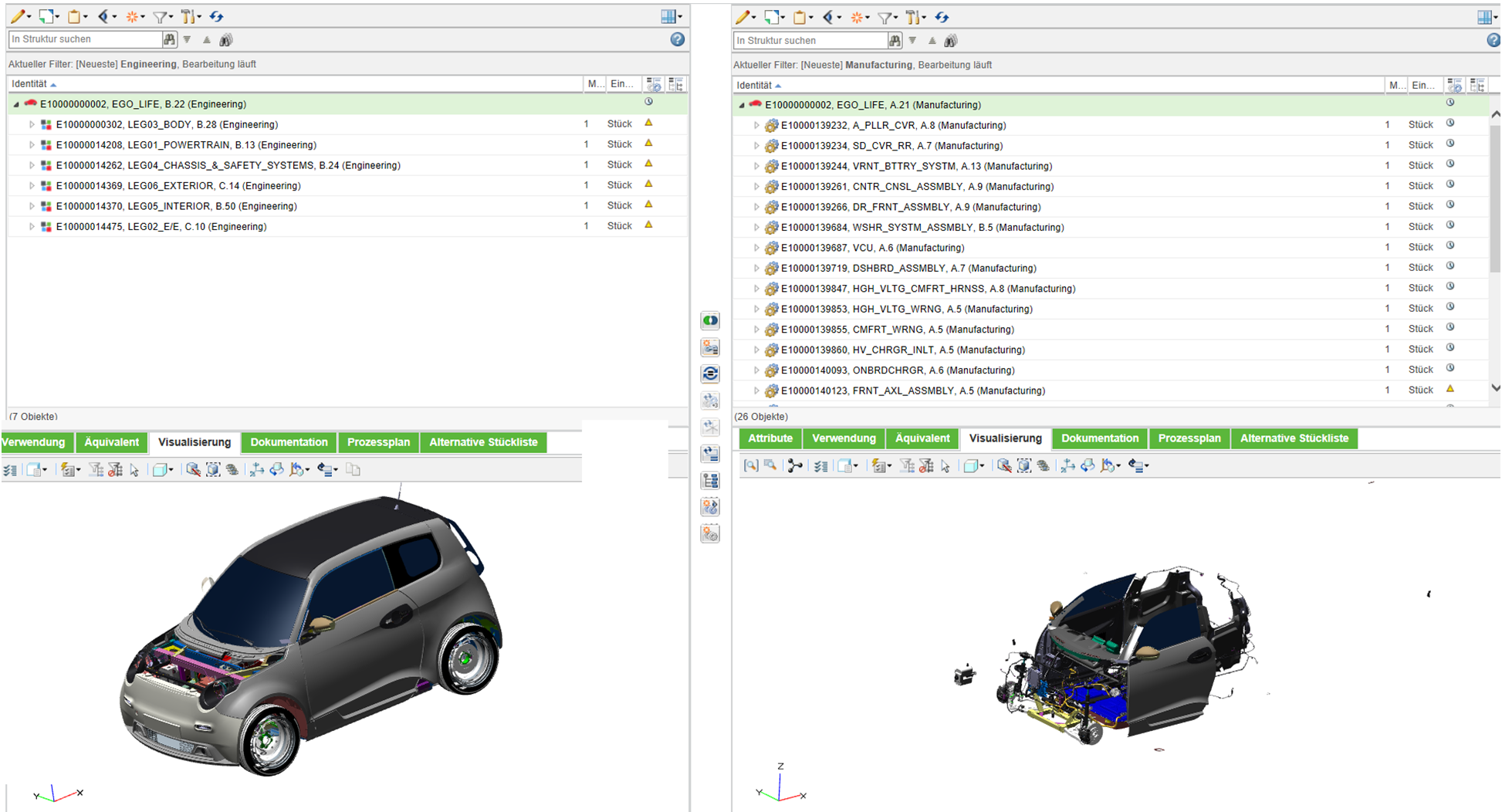

The full value of data-driven analysis depends on knowing what exactly the data refer to. In the case of product variants, or customized equipment, this is embodied in representations of the product structure, which vary across the enterprise:

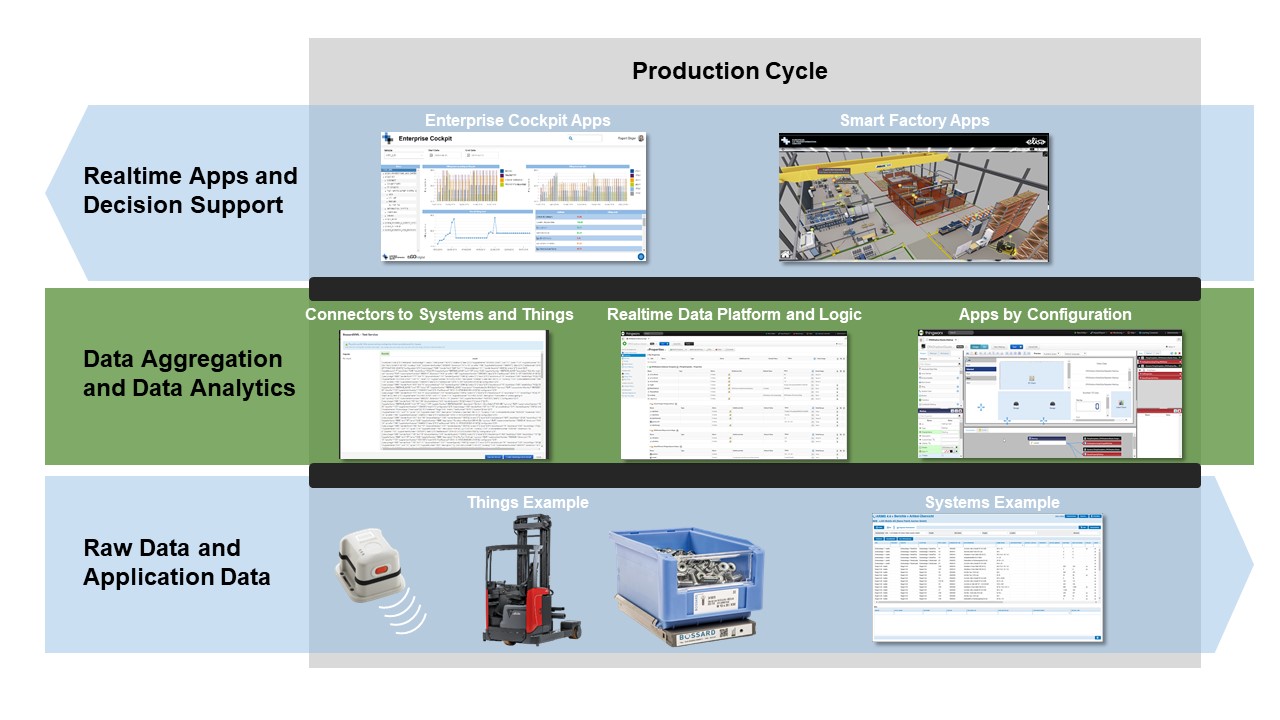

Today’s Internet of Things technologies play a key role in providing data aggregation across various systems and things. This opens new avenues for:

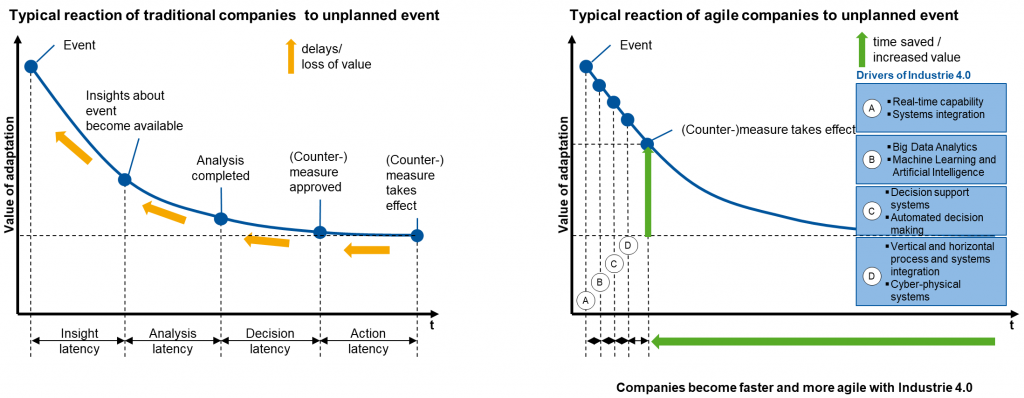

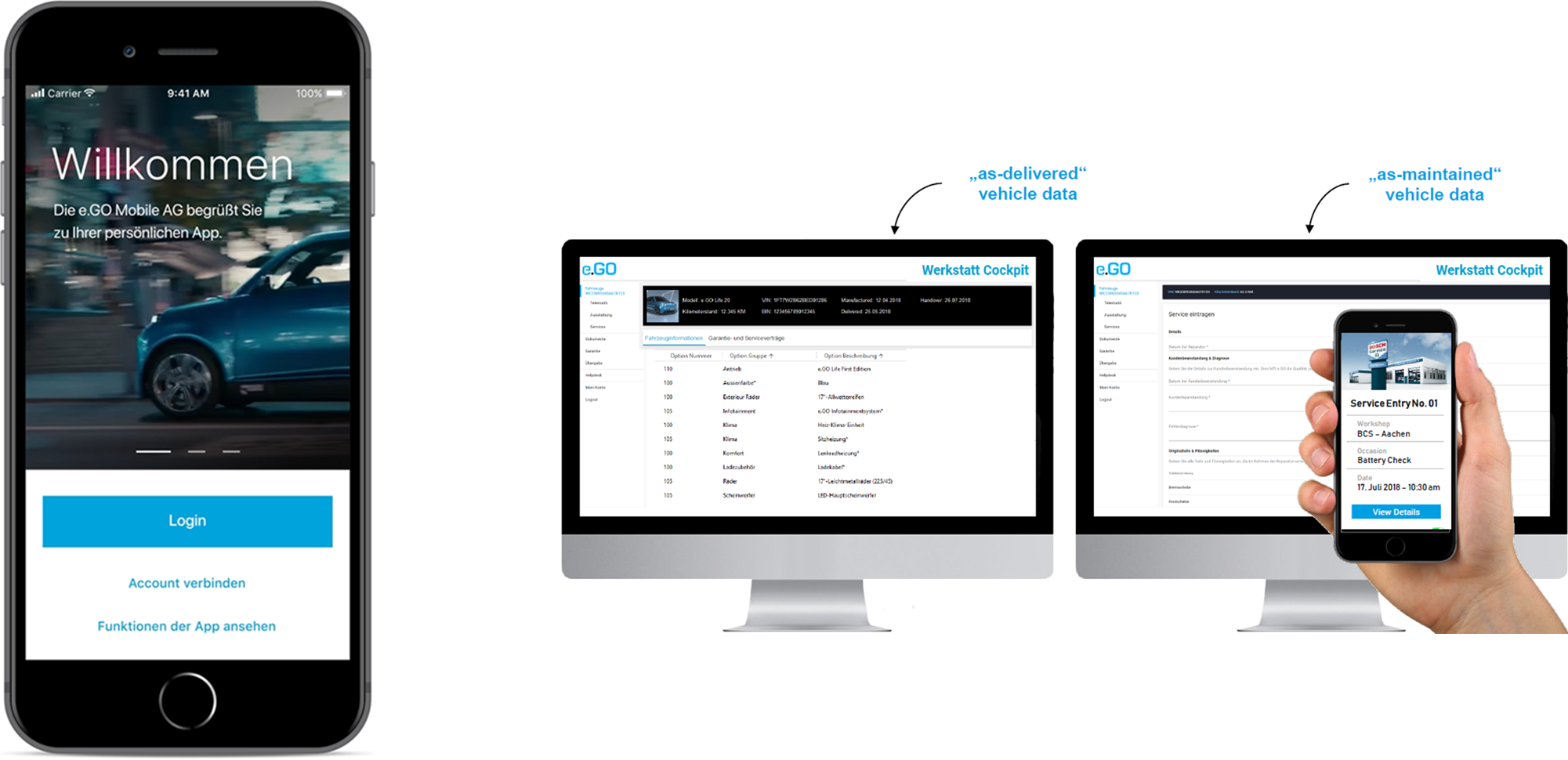

Real-time data connectivity can be done in an agile way, and in parallel to improvements related to the prior two levels “Seamlessness” and “Structures” in the Realize Digital Transformation Roadmap. This enables efficient generation of new use cases such as app-driven product and service features, data quality management, enterprise cockpits, smart factory apps for real-time production management, real-time product records, energy monitoring, preventative maintenance, just to name a few.

At the intersection or Development Cycle and Manufacturing Cycle, production engineering, especially the process planning work, typically does not receive the digital support it deserves. Other than in product design, there is a widespread lack of authoring tools and data management applications. This challenge combines with a huge opportunity in the role combining the R&D and manufacturing domains. Joining product and process engineering in the PLM system constitutes a differentiating interaction, that allows to track and manage changes between the Engineering and Manufacturing BOMs and the Manufacturing Bill of Processes in the same system, before they get released to the ERP’s master data for a given validity or configuration.

The attribute “disruptive” relates to fundamental changes in or to a given business arena. So what ends up being disruptive or not depends on the strategic business situation. Examples on the technical side might be the creation of digital twins for products, equipment, or factories and associated business and process practices. On the commercial side, charging for usage rather than selling product can constitute disruption by entering

the subscription economy which alters the usual manufacturer-dealer-consumer equations massively.

Making the Realize Digital Transformation Roadmap a successful journey depends not only on a company’s strategic orientation and top management focus. It certainly requires a good understanding of the starting point, that can be defined in step one of the 4.0 Transformation Opportunity Scan.

In our work, we have encountered two particular factors worth mentioning, as they differ significantly from the established system implementation or system migration pattern and the associated management of organizational change.

Agile deployment of digital capabilities is a prerequisite for process innovation. The reason is: If something can be truthfully specified upfront it must be known already since a long time. So the newer topics, like Internet of Things, cannot be handled efficiently with the established waterfall project sequences. Agile deployment becomes a necessity then and requires adapted management criteria, such as:

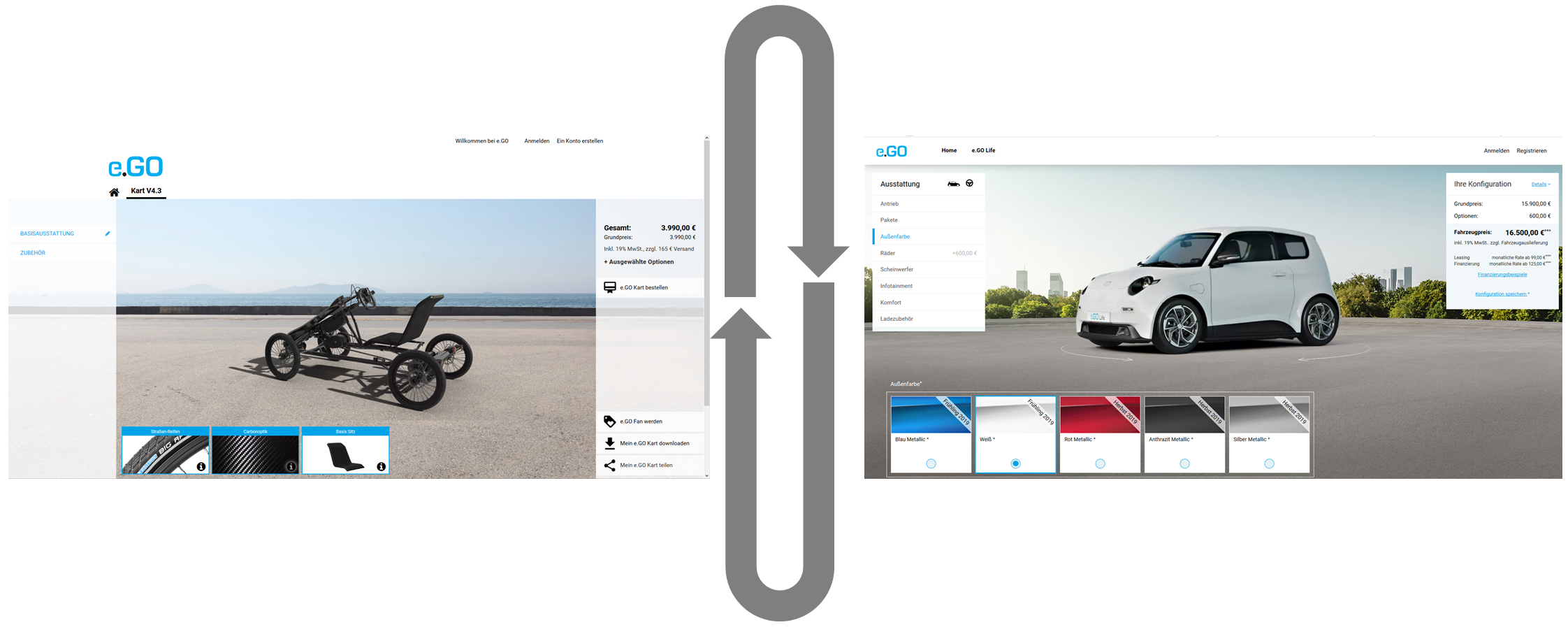

As an example, you can refer to e.GO Mobile’s website and compare the offering of e.GO Life and e.GO Kart sales configurators.