In the project SmartWirAR, an augmented reality based system was developed overlays the physical workplace with the digital plans. Connected tools lead through the wiring process.

In the project SmartWirAR, an augmented reality based system was developed overlays the physical workplace with the digital plans. Connected tools lead through the wiring process.

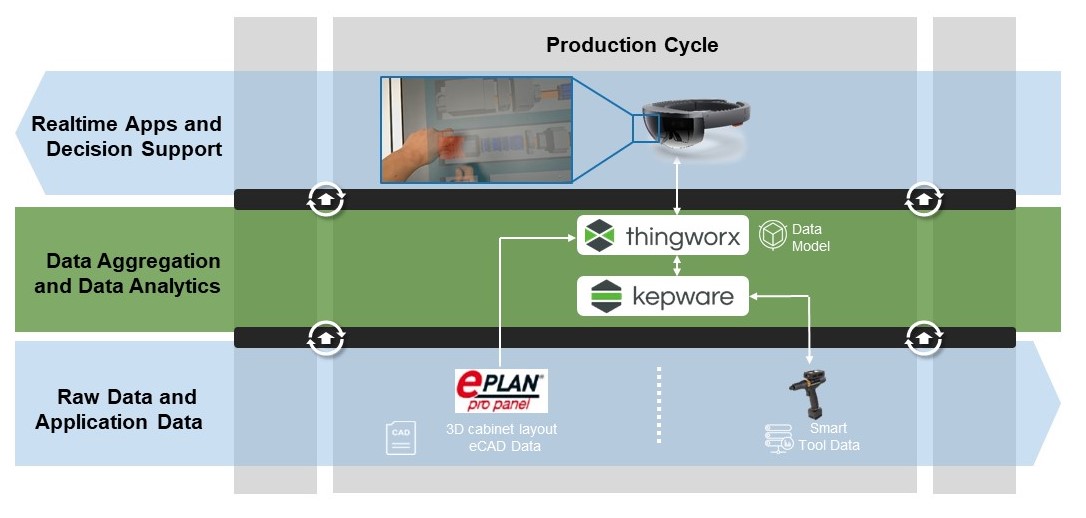

In the demonstration factory, mCAD 3D cabinet layout and logical eCAD information are joined via the internet of production architecture. All relevant information is sent to the augmented reality software. The technician sees this information in real-time as overlay over the switching cabinet, using either a tablet or a wearable such as the hololens2. It displays the components to be wired in a flashing manner. The feedback from the smart connected tools enables the system to automatically recognize completed wiring steps.

With SmartWirAR, the share of non value-creating activities is decreased significantly. The technician can focus on his primary working objectives and is guided efficiently through the process.