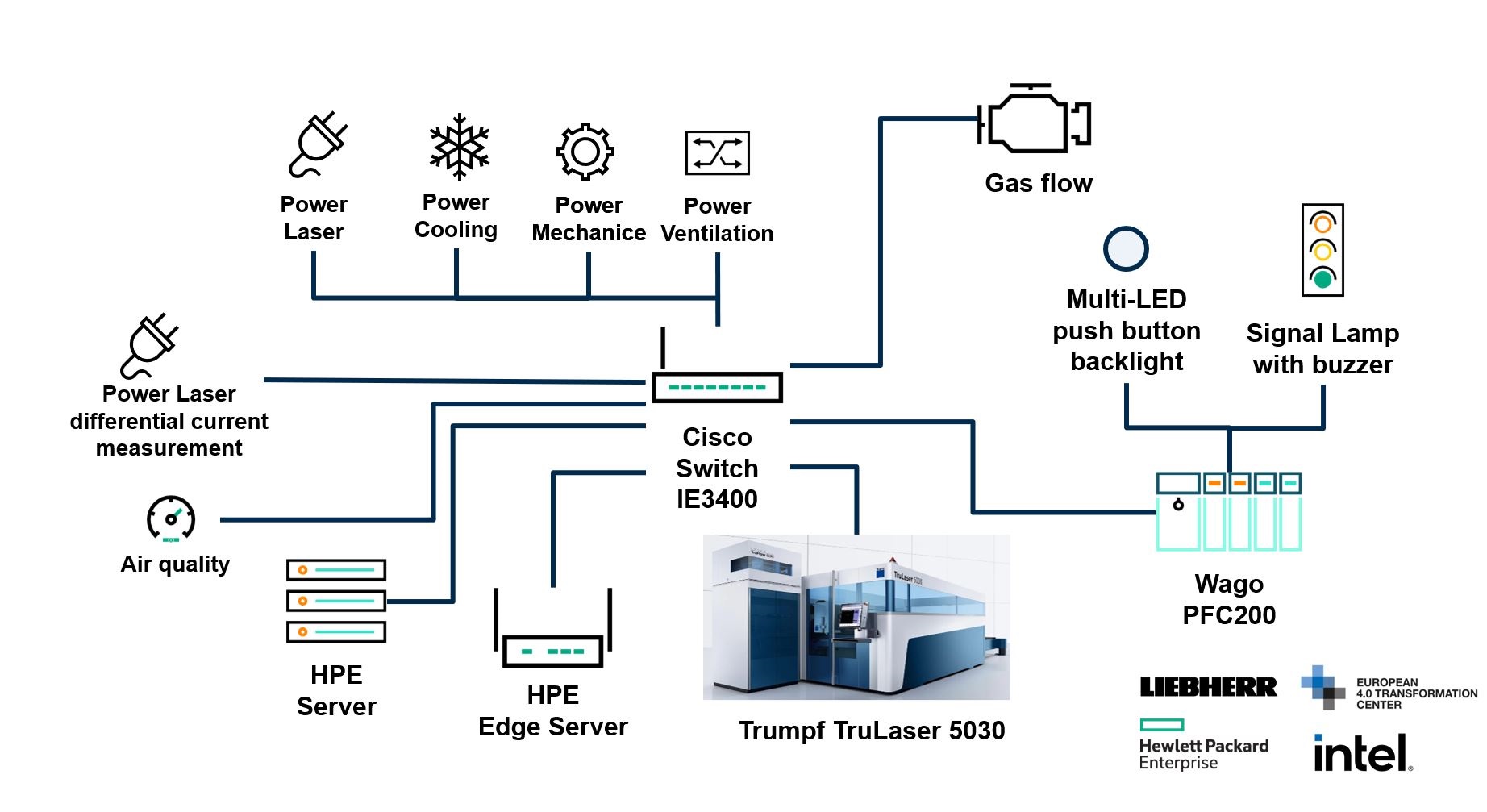

Triggered by a request from Liebherr, the E4TC and its member companies used the IIot Connector box for connectivity of an existing production machine at the Demonstrationsfabrik Aachen. In this project, IT meets OT: In the box, all signals of an active production machine and its sensors are brought together. In addition, we installed an edge server from HPE as central computing unit. To achieve a scalable and maintainable architecture, a microservice-based approach was used.

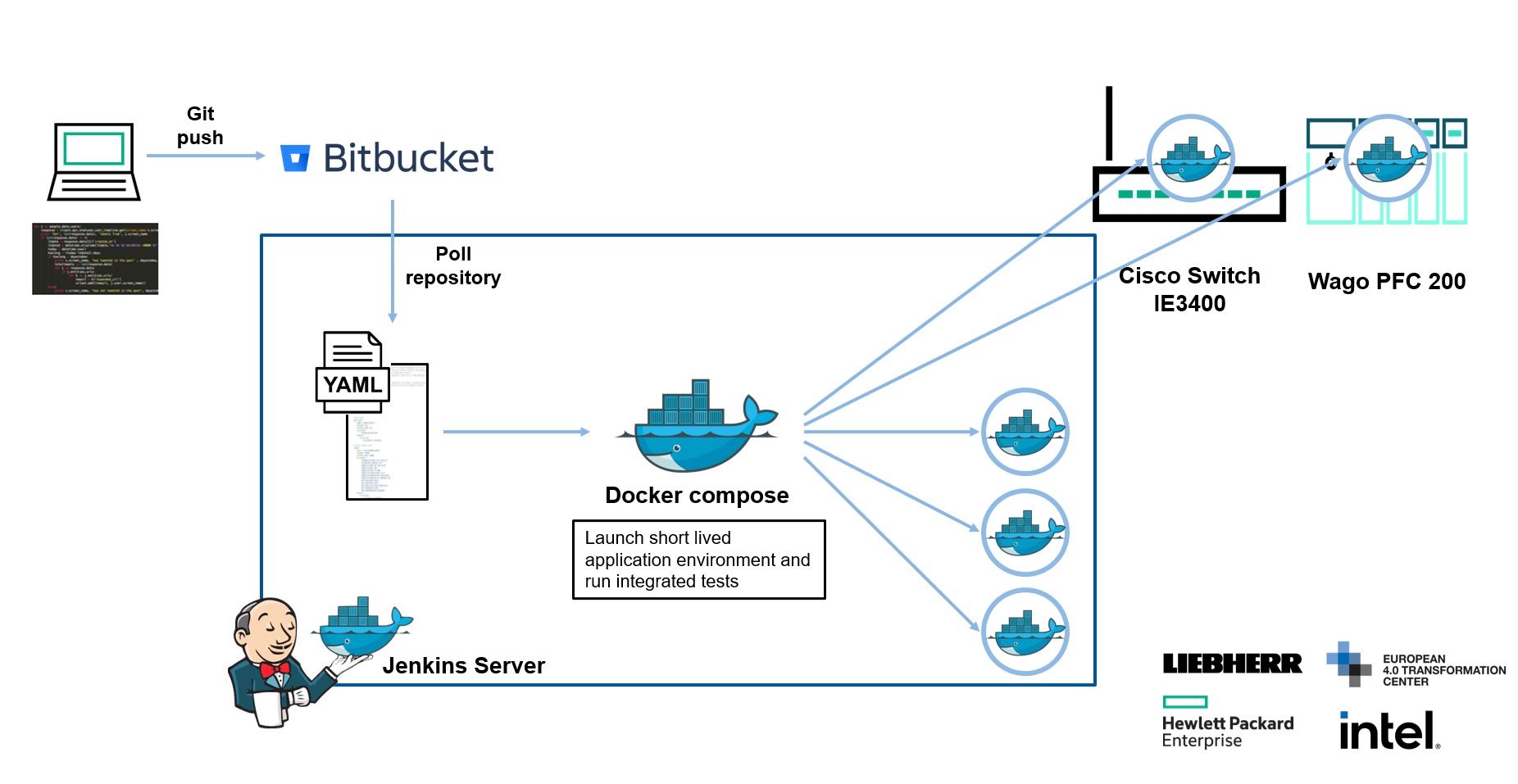

This way, any data source can be connected via microservices. Different formats and interfaces are considered, harmonized into a unform and standardized data format and provided centrally. As the interface to the rest of the architecture is standardized as well, the microservices are independent of either programming language or hardware. Data is available for various use cases in real time. At the same time, maintenance and connectivity are facilitated, was all information culminates in one point. The solution is tailored for both scalability as well as reproducibility. As the preprocessing is done close to the fabrication machine directly at the edge, time-critical use cases can be implemented in a high-performance and cost-efficient manner.